Roland DG Collaborates on Yokohama Triennale Original Merchandise Development Workshop

03/07/2024 Corporate Activities, Digital Printing

In March 2024, the 8th Yokohama Triennale international contemporary art exhibition will open in Yokohama City. Prior to the opening, a participatory merchandise development workshop was held. Roland DG provided the new VersaSTUDIO BD-8 flatbed UV printer and assisted in bringing the ideas of future creators to life.

Yokohama Triennale conducts original merchandise development workshop

Hosted by : Organizing Committee for Yokohama Triennale, NTT East, NTT ArtTechnology

Technical Support : Digital Fabrication Association, FabLab KandaNishikicho

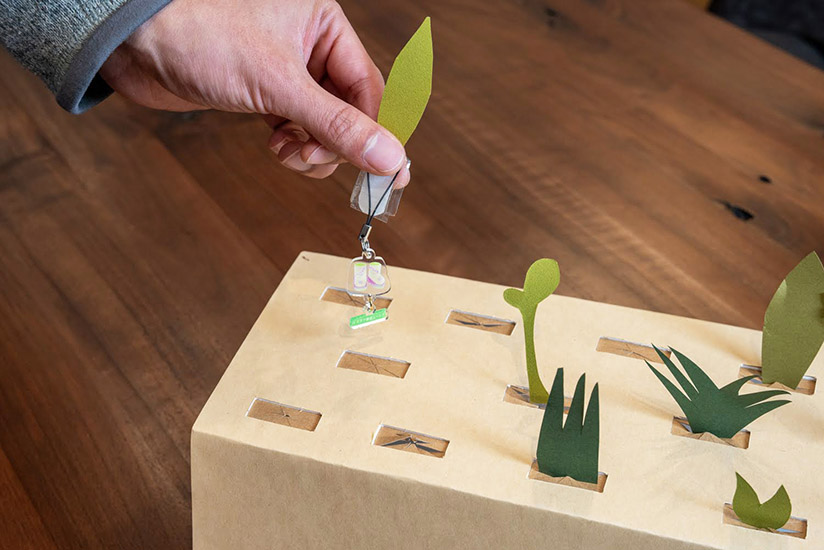

The workshop involved 35 participants ranging from high school students to individuals in their 70s who formed teams for the first time. They tackled the design and prototyping of merchandise based on the “Wild Grass: Our Lives” theme of the 8th Yokohama Triennale, presenting their creations to the judging panel with the goal of commercialization.

Click here for more details on the workshop (Japanese text only)

Bringing ideas to life with digital fabrication

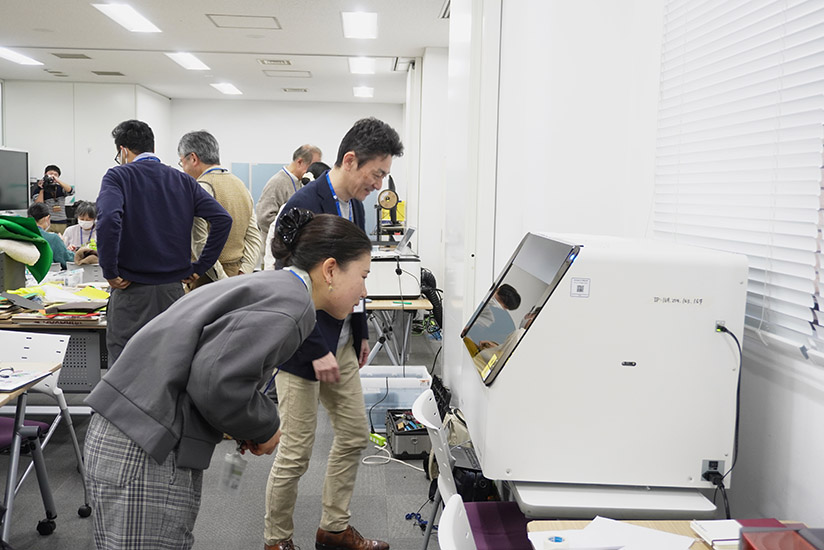

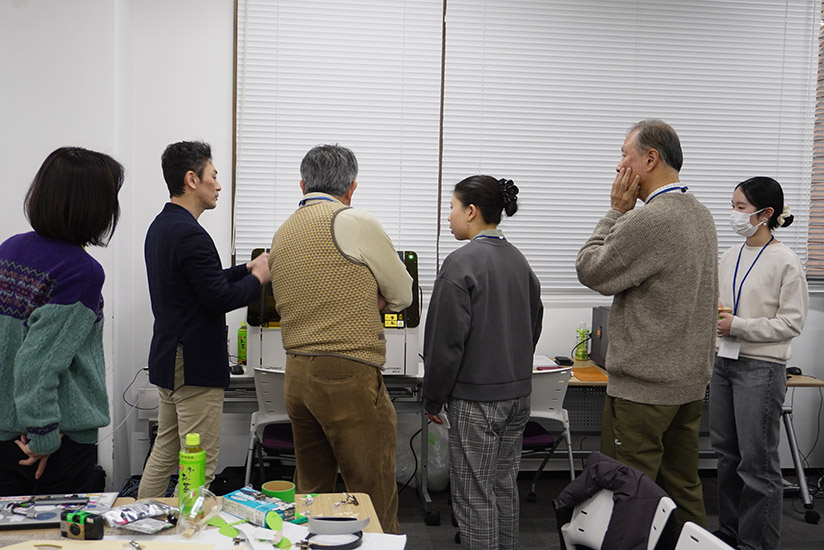

During the prototyping sessions held on January 20 and 21, each team utilized digital fabrication equipment such as UV printers, laser cutters, 3D scanners, and 3D printers with support from specialist staff to complete their prototypes.

-

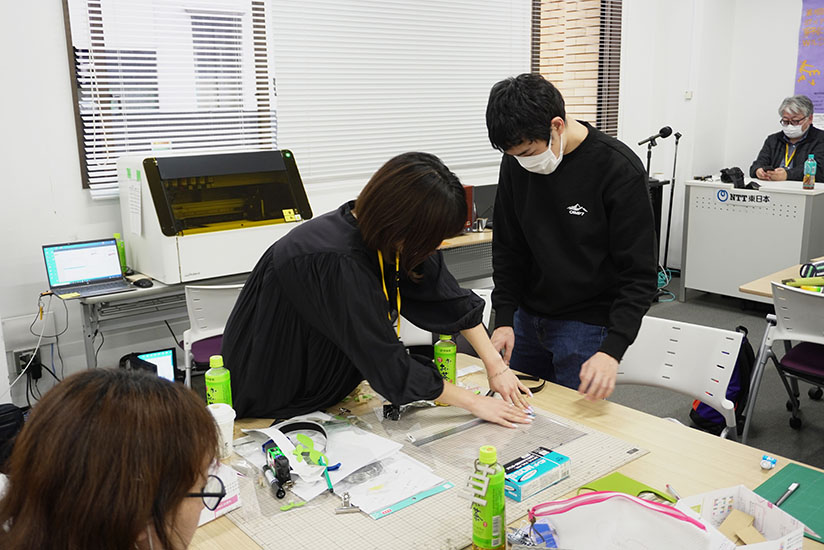

Creating prototypes using a combination of analog and digital methods

-

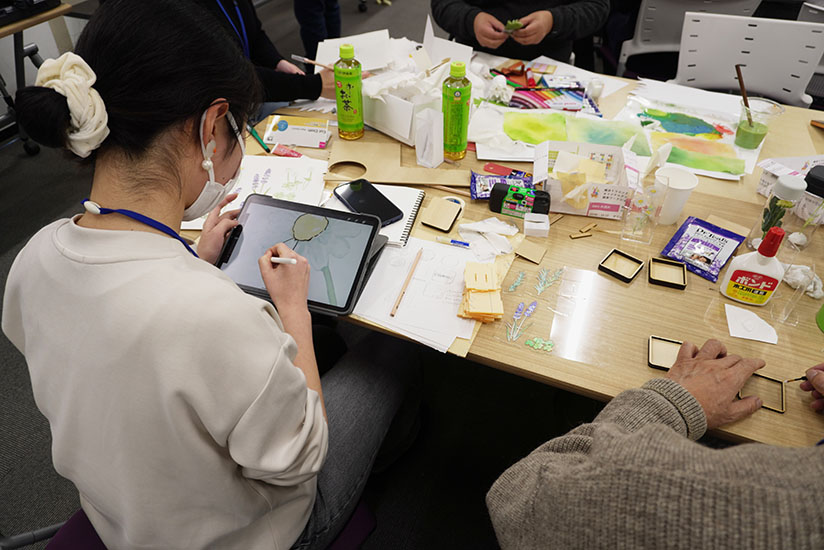

Design data being prepared on-site

Roland DG has long been committed to developing products that make digital fabrication accessible and to spread the enjoyment of creativity to everyone. As a result, we offer a lineup of compact, affordable and easy-to-use desktop fabrication tools under the VersaSTUDIO brand.

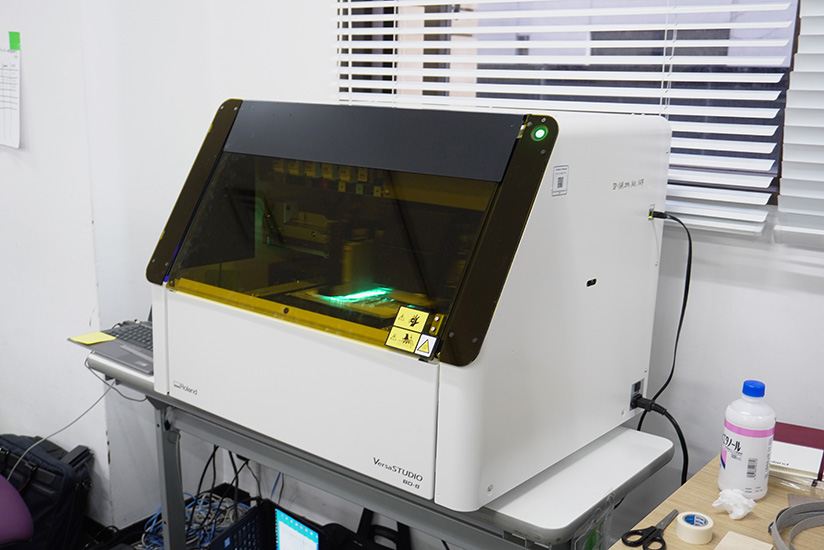

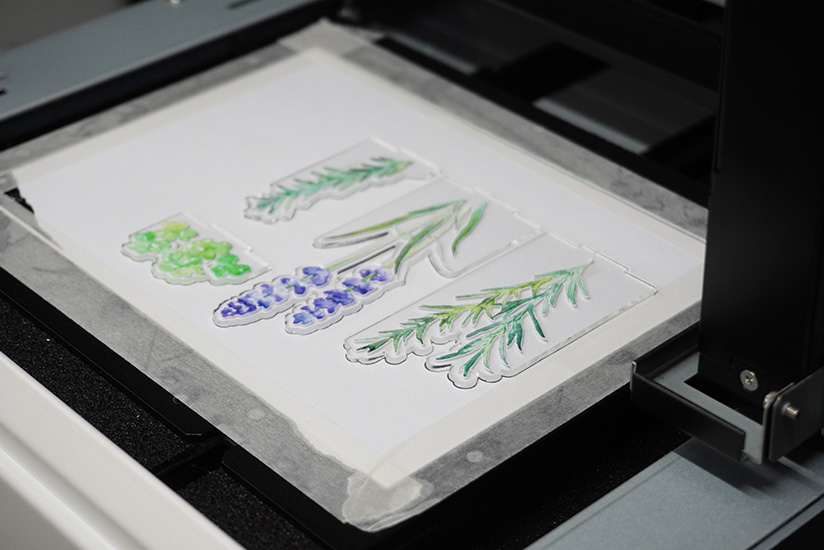

As part of our support for the workshop, we provided the BD-8 which is the first UV printer under the VersaSTUDIO brand. Despite its compact desktop size, it’s capable of direct printing on various materials like acrylic, paper, and fabric. The workshop aimed to swiftly transform participants’ ideas into reality, aligning with the essence of VersaSTUDIO’s concept. With its ability to instantly cure ink with UV light, the BD-8 enables swift progression to subsequent production processes after printing, making it ideal for prototyping.

Teams utilized design data created from sketches and photos to print acrylic parts, exterior paper boxes, fabric, etc., using the BD-8 to bring their envisioned ideas to life.

-

Compact UV printer BD-8

-

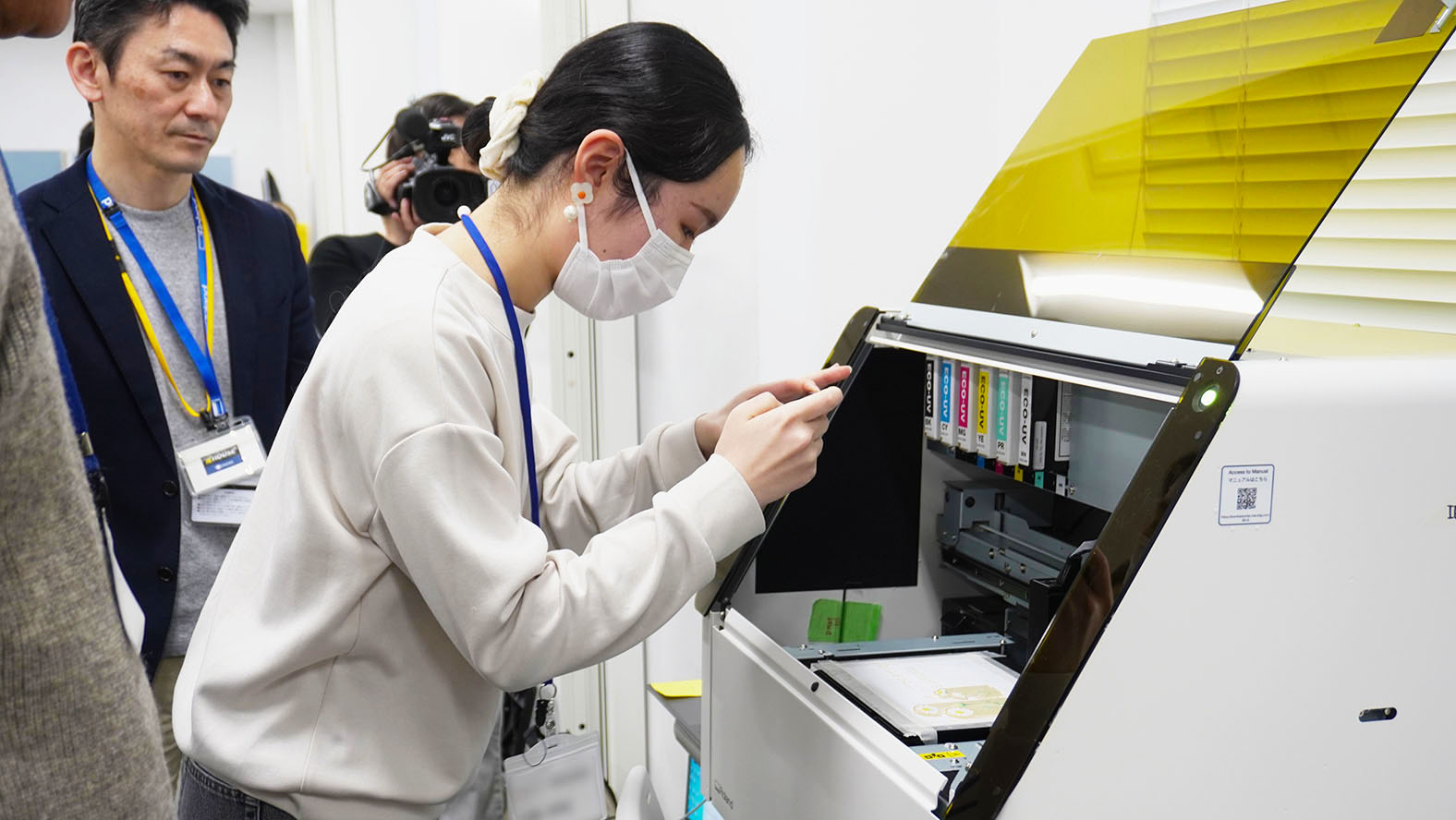

A close look at the printing process

-

Keen interest in seeing the UV printer for the first time

-

Custom design for an exterior paper box

-

Printing design data on-site

-

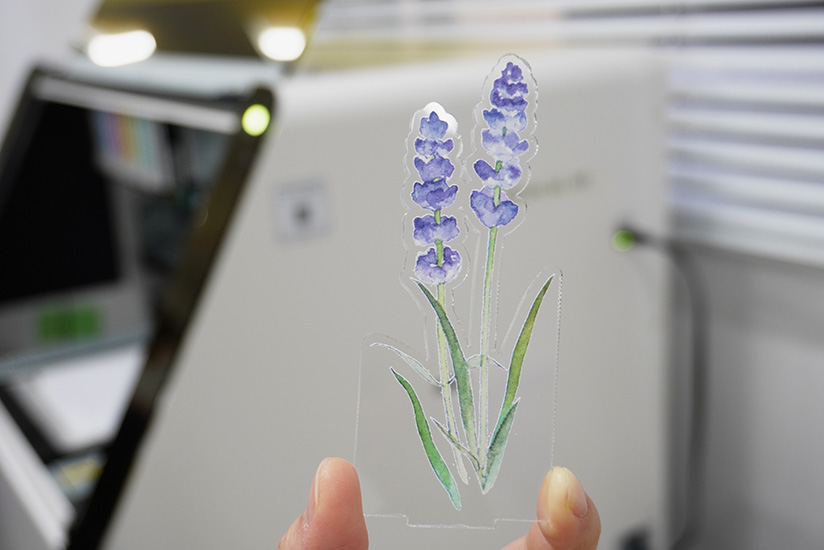

Faithful reproduction of delicate sketches

During the judging session held on February 4, each team presented their projects and prototypes. The winning entry will be commercialized and available for purchase during the event as “Future Creator Merchandise” on the 2nd floor of the Yokohama Marine Tower and other shops. Additionally, other teams’ projects and prototypes will be exhibited there. We invite you to explore the variety of ideas presented.

Watch the judging session video here.

-

“Wild Grass Gacha,” the winning piece. Acrylic charms featuring randomly selected wild grass printed using the BD-8

-

One of the featured prototypes received a special award. When using herbal (wild grass) scented bath salts, wild grass illustrations appear inside the container. Printed using the BD-8 on acrylic parts.

Many participants encountered digital fabrication equipment for the first time and expressed sentiments such as: “It was fresh and very enjoyable,” “I was able to realize ideas that my skills couldn’t keep up with,” and “With the UV printer, I was able to create a prototype almost identical to the product image.”

We are delighted to have supported participants in realizing their ideas through the UV printer, sharing the joy and excitement of bringing imaginations to life.