Fabrication Workshop Makes Learning Circuitry Fun — Part 2

11/27/2017 Events & Tradeshows, 3D Digital Fabrication

In the first part of this series, we provided details of a recent fabrication workshop based on the concept of providing a fun approach to learning the basics of electronic circuitry. In this part, Kazuharu Muramatsu of the company’s DGSHAPE Market Development Department who planned the workshop, and Fab Lab Hiratsuka Director and Associate Professor of Kanagawa University Faculty of Business Administration, Daisuke Doyo, who was the instructor at the event, talk about the background to the workshop and their thoughts after holding the event.

First up, we asked Muramatsu about his feelings on the workshop.

Tell us more about the background and purpose of organizing this workshop.

Muramatsu: Roland DG’s 3D milling machines have mostly been used at technical high schools and university labs for education and research purposes, but are starting to be used for a greater range of applications in recent years, including at general curriculum high schools and makerspaces like Fab Labs. While we were approaching new markets like these, we found many people were looking for fresh ways to enhance programming and fabrication courses to give children and students a more central role in planning and production.

Roland DG has long been a key driver in providing an approach to fabrication environments that anyone can take part in for “Transforming Your Imagination into Reality.” We thought that our products might have the potential to help these people come up with solutions or give them tips along the way.

So we started looking into ways we could provide an exciting new hands-on approach to electronics manufacturing and programming which are the keys to fabrication. Our focus was on people who are central to broadening the scope of all types of fabrication, such as science and technology teachers and people operating Fab Labs and other fabrication spaces.

Muramatsu providing an overview of the workshop.

What future aspirations do you have for the workshop?

Muramatsu: Until we actually held the workshop we were concerned about many factors, like whether people would be able to complete their projects in the available time. Yet participants had a lot of fun while working on their projects and the event went much better than we expected. The feedback we received was also very positive, with teachers telling us how they could picture themselves applying similar ideas at their schools. In addition to schools and makerspaces, we also think that courses on fabrication could be implemented for personnel skills training at companies. I hope that workshop participants will apply the experiences and new methods that they learnt to their own workplaces and help spread this knowledge. All the methods we used at the workshop are also listed on the website, and hopefully they can be customized to suit each classroom or workplace.

* Download workshop methods and procedures here:

https://fabble.cc/fablabhiratsuka/adaptationboad-en

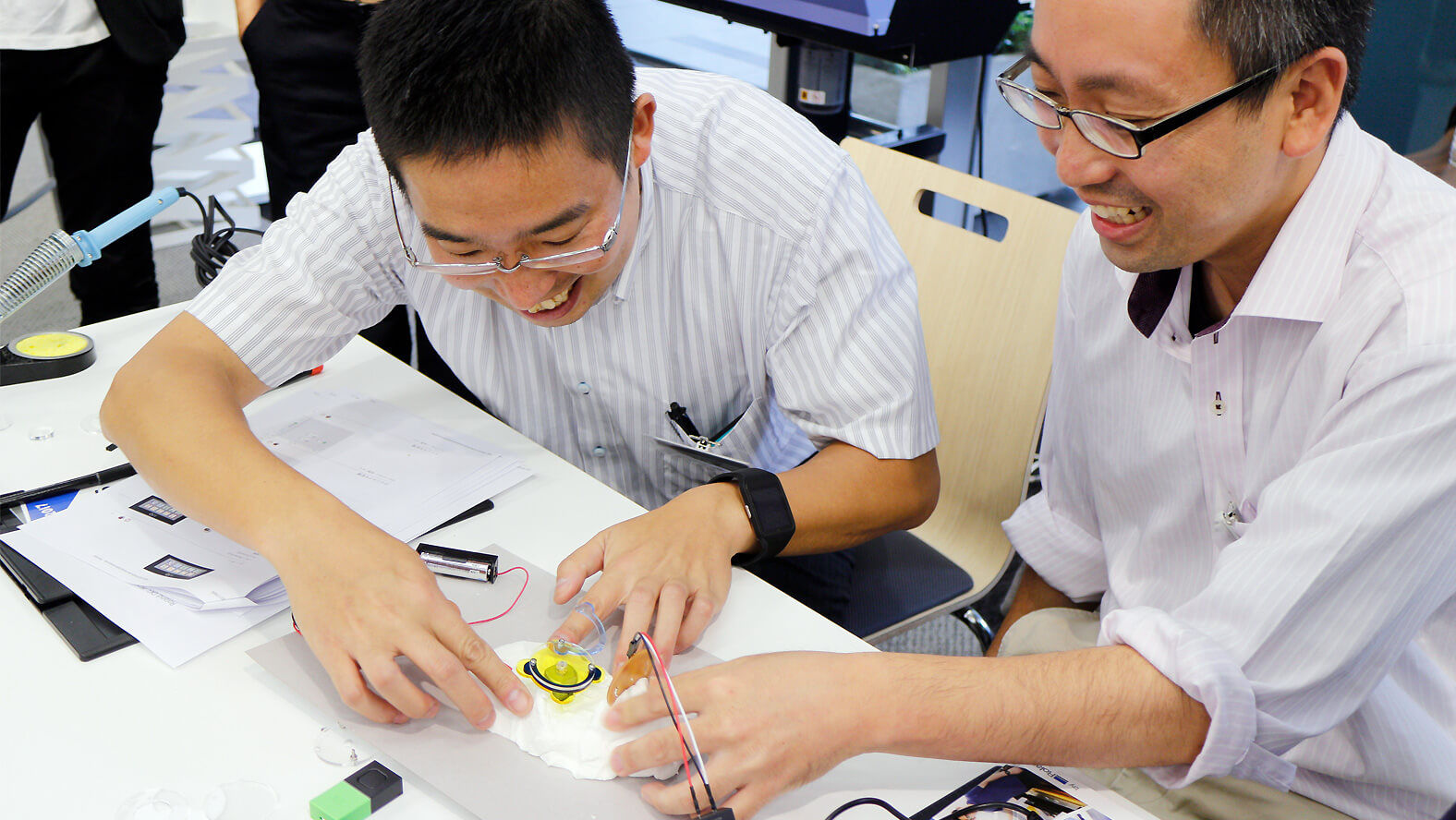

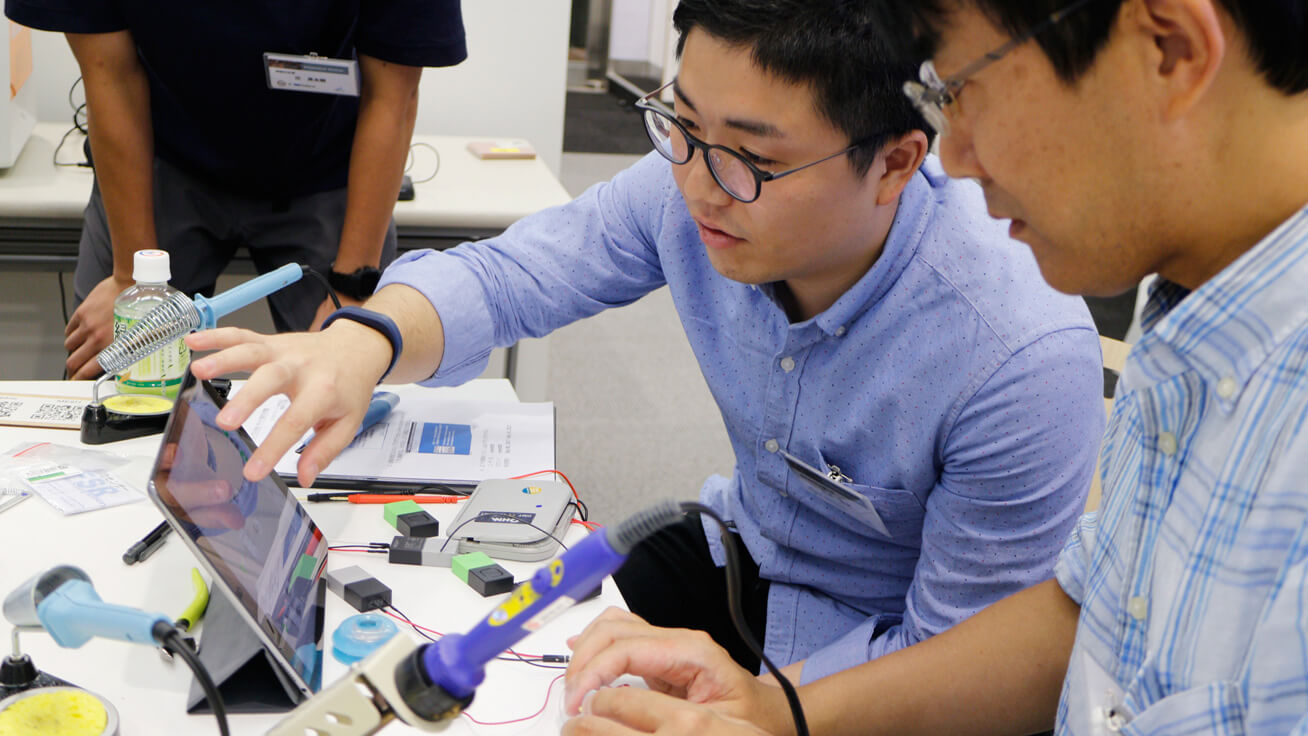

Attendees working on projects at the workshop.

Participants presenting their projects.

We also asked Professor Doyo, who was the instructor at the workshop, about his thoughts on the event as a member of the teaching staff and manager of Fab Lab Hiratsuka.

* Fab Lab Hiratsuka

The first Fab Lab in Japan operating on a college campus. The Fab Lab is known for its unique system where Kanagawa University Faculty of Business Administration students are involved in operation. The lab is also available to the general public and students play an active role in interacting with the local community.

http://www.mgmt.kanagawa-u.ac.jp/fablabhiratsuka/ (Japanese only)

Daisuke Doyo, Associate Professor of Kanagawa University Faculty of Business Administration and Fab Lab Hiratsuka Director.

What were your impressions in running the workshop?

Doyo: As the event organizer it was great to see participants much more focused on their projects than expected and making some wonderful creations. It was also great fun for me as well. After a short time, participants who had just met each other for the first time were communicating smoothly and cooperating while making their projects, and I think they all had fun while learning something new.

What was the background that led to your involvement with this workshop?

Doyo: The university system means that there is a significant separation between the arts and sciences, which limits the opportunities for arts students to come in contact with anything related to science. Yet I think it is important for these students to acquire science knowledge and skills such as electronics and programming. Instead of students limiting their own potential by labeling themselves as arts students, I want to see them learning a broad range of skills to provide the drive to come up with new ideas and become involved in a broad range of concepts. Armed with new experiences, they will hopefully be able to go on and live an even more rewarding life. I came up with the idea of a workshop focused on electronics manufacturing as a place where students could acquire these skills and – at almost at exactly the same time --Roland DG, which had a similar concept in mind, approached me asking if we could plan something together, and so I ended up assisting with this workshop.

Professor Doyo explaining to participants how to have fun with electronics manufacturing and programming and apply their knowledge.

It was impressive watching student staff from Fab Lab Hiratsuka providing assistance to workshop participants. What did you feel when you saw this?

Doyo: Fab Lab Hiratsuka is usually open to members of the public outside of the university system. Students show members of the pubic how to operate the equipment, and also learn many things when fabrication professionals come to use the facilities. Even during this workshop, there were many times when student staff learnt new things while providing support, which made it a great learning opportunity for them. They also experienced playing a key role in running the event with a major corporation, and this is sure to be beneficial to students. In fact, the students focused much more seriously and with a stronger sense of responsibility from the preparation stage through running the event on the day of the workshop.

Student staff from Fab Lab Hiratsuka assisted participants with producing their creations.

Will it be possible to run the same program at schools or Fab Labs?

Doyo: We did not set any specific objectives for the workshop – participants were free to make whatever they wanted. As I witnessed them communicating with each other and having fun as if they were kids again, I felt that the workshop program has a great deal of potential to offer. The program was quite advanced because it included elements of electronics manufacturing and programming, but I consider the content to be very appropriate for implementing at schools or other Fab Labs where participants can have fun by utilizing the easy-to-use tools that were available during the workshop.

A final note to the 2-part series: While electronics manufacturing and programming are complex topics, the workshop was designed to be fun to learn by using tools like the 3D milling machine and the MESH platform. Feedback from participants indicated that they had fun making things through repeated trial and error, concentrating and cooperating with different people during the few hours of the workshop, and that they would like to implement a similar program at their own school or makerspace.

Roland DG will continue designing and supporting initiatives aimed at familiarizing fabrication and making it more accessible to everyone.