OSAKA FUORI SALONE 2025 Exhibition Demonstrates the Possibilities of Powder 3D Printers

10/23/2025 Corporate Activities, Events & Tradeshows, Digital Printing, 3D Digital Fabrication

Roland DG used its powder 3D printer announced in January this year to produce interior building materials in collaboration with NOMURA Co., Ltd. to exhibit at “OSAKA FUORI SALONE 2025” held September 10 - 16 in Osaka and sponsored by the OSAKA FUORI SALONE Executive Committee. “Prototype Pattern TATEWAKU” was designed by NOMURA’s designer Mr. Keisuke Yoshida and printed with the PB-600/PB-400 powder 3D printer.

Newest technology meets tradition

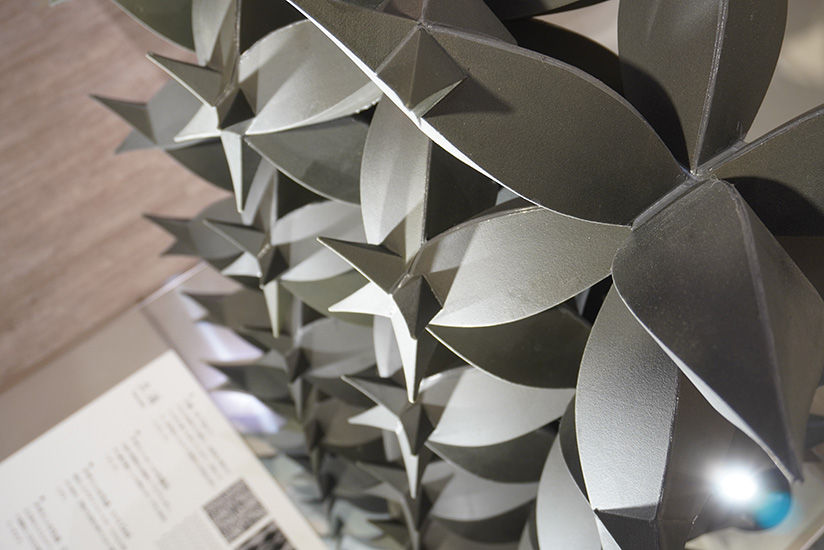

The “Prototype Pattern TATEWAKU” motif is a traditional Japan pattern. “TATEWAKU” represents the rise of water vapor and clouds and has adorned kimonos and everyday items for centuries. For the exhibition, the characteristic curves of “TATEWAKU” were programmed and designed as a three-dimensional object and printed with a powder 3D printer.

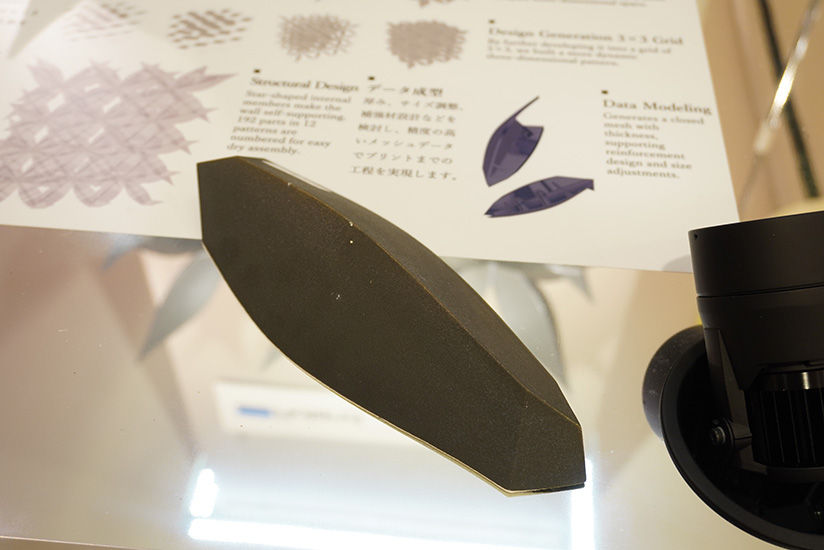

The “Prototype Pattern TATEWAKU” was made by combining 192 parts with 12 patterns. The ceramic powder used in the PB-600/PB-400 powder 3D printer has an excellent shrinkage rate of less than 1% after firing, allowing for precise molding of the design, and making it possible to achieve a self-supporting wall that combines many parts.

Mr. Keisuke Yoshida is a member of the NOMLAB team which is active in Future Creation Laboratory. The team’s mission is to pursue and create the possibilities of space with a variety of technologies and is researching the use of powder 3D printers.

The “Prototype Pattern TATEWAKU” was printed with a powder 3D printer at Roland DG’s headquarters in Hamamatsu City, Shizuoka Prefecture before being glazed and fired at a long-established kiln in Seto City, Aichi Prefecture, and then assembled at a partner factory in Nagoya City. On the first day of the event, Mr. Yoshida saw the actual completed work for the first time. He said, “I was happy that the design took shape and was surprised at how elaborate it was.”

-

“Prototype Pattern TATEWAKU”

-

The Roland DG and NOMURA booth

-

An example of the parts of “Prototype Pattern TATEWAKU”

-

Various samples produced by powder 3D printers

From Osaka to the world

“OSAKA FUORI SALONE” is an event that introduces artistry that enriches life, with a focus on architecture and furniture. The theme of the first-time event was “an intoxicating lifestyle.” The event promoted the concept “to enjoy life as if you were savoring it with all five senses in everyday life” and “to immerse yourself in beauty, space, senses, and time.” Eleven companies, mainly manufacturers of building materials and interiors, participated.

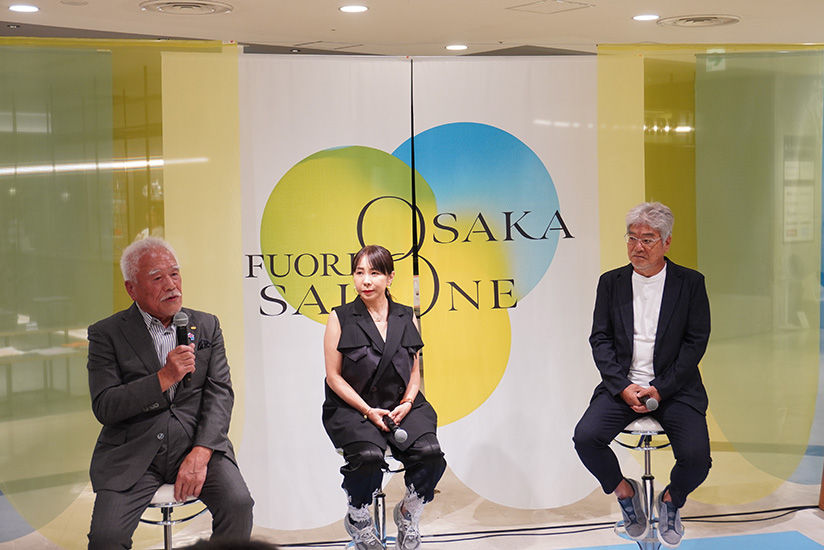

On the first day of the event, an opening ceremony was held. Mr. Toshiaki Nishioka, the founder and representative of the executive committee, explained the significance of the event, saying, “With the Osaka Expo 2025 being held, many people from all over the world are visiting Osaka, and we wanted to create a place for interior design manufacturers to communicate to the world.”

Ms. Yuko Nagayama, architect and the event director, talked about the value of OSAKA FUORI SALONE, “There are few design events where manufacturers strongly communicate.” She said, “I hope that people will feel the atmosphere of the beginning, where more and more people will mix and new things will be born at this event.”

-

Opening event held on a special stage

-

Talk given by promoters and event directors

-

Event director explains venue decoration

-

Designer Mr. Yoshida explained his design at our booth

Our solutions expand the possibilities of interior design

The “Prototype Pattern TATEWAKU” that was the center of our booth was realized by combining the respective technologies of our powder 3D printer with the design by NOMURA designer Mr. Yoshida, and work of various pottery craftsmen. Everyone who saw the completely new interior design method was interested in how to make it. In addition, we introduced the possibility of decorating the space with original tiles made with the powder 3D printer and samples using the 2.5D surface printer DIMENSE.

This event, which was visited by numerous people involved in interior and interior building materials, attracted a lot of attention and high interest, especially for “Prototype Pattern TATEWAKU.” I hope that everyone who saw it was able to have an “intoxicating experience” as the theme of the event through the spatial production using powder 3D printers and 2.5D surface printers DIMENSE.

We aim to propose a wide range of new interior and interior building materials through the combination of designers, craftsmen, and powder 3D printers going forward from this event.

-

Explaining the process to visitors

-

DIMENSE printing samples

-

Designer Mr. Yoshida explained his design

-

Close up of Prototype Pattern TATEWAKU