Renault Sport Formula OneTM Team Selects Roland DG for World-class Motorsport

07/03/2018 Digital Printing, 3D Digital Fabrication

Renault Sport Formula One™ Team unveiled the new livery for its racing car in February: a slick black and yellow design with graphics printed with Roland DG equipment. In a recent interview, a team spokesperson provided more information about this ongoing collaboration.

Renault Sport Formula One™ Team has relied on Roland DG for its racing car vehicle graphics for a number of years, using a TrueVIS VG-640 wide-format inkjet printer/cutter at its Technical Centre in Enstone, Oxfordshire, where its racing cars are designed and manufactured. The paint and graphics studio was on total lock-down ahead of the livery launch, with its staff sworn to secrecy over the design.

The racing machine in progress at Renault Sport Formula One™ Team's Technical Centre.

Renault Sport Formula One™ Team's cars will compete in 21 Grands Prix around the world this year, with a cumulative audience of more than 400 million viewers. Brand exposure plays an essential role in sponsorship programs and it is essential that the livery is reproduced accurately. If any sticker gets damaged or dirty, the team will replace it immediately.

Joe McNamara, Head of Paint and Graphics at Renault Sport Formula One™ Team, explains that, to make sure this is possible, racing cars always travel with a number of sticker sets, all printed on the VG-640.

Joe McNamara, Head of Paint and Graphics at Renault Sport Formula One™ Team, poses with their Roland DG printer/cutter and vinyl cutter.

"The team always carries 30 versions of every sticker so they can be replaced if needed. This amounts to around 1,400 stickers for every race," he says. "Eighty per cent of the stickers are sponsor-related so they have to be replaced with absolute precision."

While normally Renault Sport Formula One™ Team's expertise makes this process go as smoothly as changing a tire, Joe McNamara knows he has the back-up of Roland DG users around the world who can print the designs quickly and accurately if need be.

"It's comforting to know that, if necessary, I can find a graphics company with a VG-640 that is local to the track, to whom I can email a file and all they need to do its hit 'print' at their end to produce perfect stickers," McNamara said. "I won't see a difference between their stickers and ours."

"We really are part of a Roland DG family, all over the world."

In addition to the TrueVIS VG-640 printer/cutter, the Renault Sport Formula One™ Team studio uses a CAMM-1 GR-640 vinyl cutter.

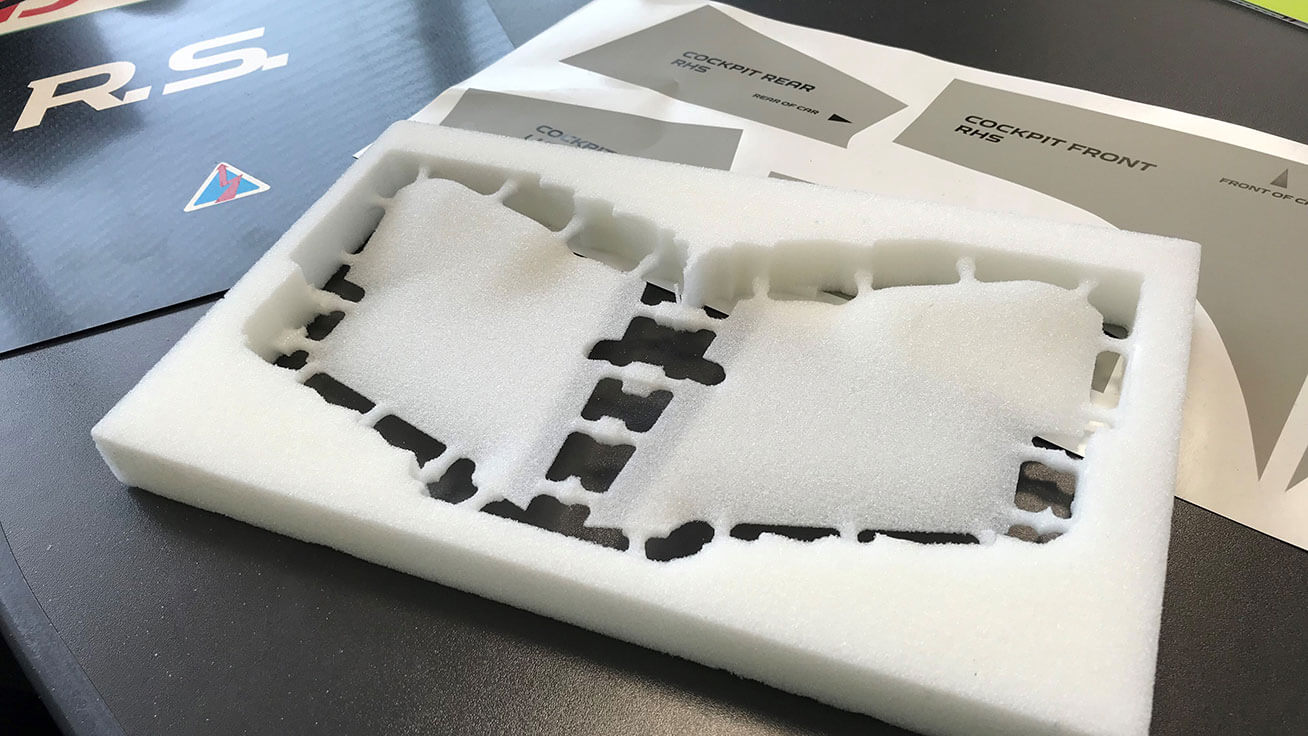

The team also uses four MDX-540 milling machines to manufacture lightweight car parts from high-performance Rohacell® foam core.

"The Roland DG MDX machines are known here as phenomenal workhorses; they just don't go wrong," says McNamara.

Four MDX-540 mills are installed at their Technical Centre.

Components manufactured using the MDX-540 mills are inserted in the front and rear wings as well as other car parts to provide increased structural integrity.

"In fact, every Roland DG machine we use is hugely reliable. The VG-640 is quick, accurate, easy to operate and easy to clean and the four MDX machines are simply bulletproof."

"We don't have downtime here", McNamara said. "It's not an option."

For more information about Renault Sport Formula One™ Team, please visit www.renaultsport.com.