Making tote bags and stickers enlivens work experience program for elementary and junior high school students

09/29/2025 Corporate Activities, Digital Printing

On July 29 and 30, we sponsored the “Hamamatsu Miraiko” project, in which elementary and junior high school students in Hamamatsu City visited local companies and experienced work life. We held a work experience program using our printers for the first time. Participants created their favorite designs on their computers and made tote bags and stickers.

Giving shape to your “likes”

The “Hamamatsu Miraiko” project sponsored by Hamamatsu City provides an opportunity for elementary and junior high school students in the city to visit local companies and experience work during the summer vacation period in order to convey the appeal of work to the children who will lead the next generation. As a company headquartered in Hamamatsu, we decided to implement it based on a long-held desire to let children know more about Roland DG.

A total of 48 people from 4th grade elementary school to the 3rd grade of junior high school participated in the program. It was divided into four sessions over two days. The experience session started with an explanation of how our purpose of “To Empower Creativity and Excitement Worldwide” is being used in manufacturing. We introduced what can be made with different types of printers and displayed some familiar items such as signs, goods, and clothes made with our products.

After the explanation, the tote bag-making began. We divided “what I like” into the process of “putting it into words”, “turning it into a picture”, and “giving it shape”.

First, participants in groups at each table wrote down their likes on paper and presented them. By putting their likes into words, we had them experience how manufacturing begins.

Next, in the “painting” process, participants expressed their “likes” in words by using PowerPoint on their computers and pasting their favorite illustrations and adding letters. Although the number of designs in PowerPoint is limited, each participant created their own design while being creative and consulting with other participants. By verbalizing, visualizing, and sharing their thoughts with other participants, they were able to experience the feeling of working.

Once the design is complete, participants proceeded to the “shape” process. The tote bag was produced using the TY-300 DTF (Direct-to-Film) printer . Participants glued their designs printed from the printer onto the transfer film and pressed them onto the tote bag. Peeling off the film revealed the design vividly. When we saw their “likes” taking shape and the children happy, we also felt the joy of making things again.

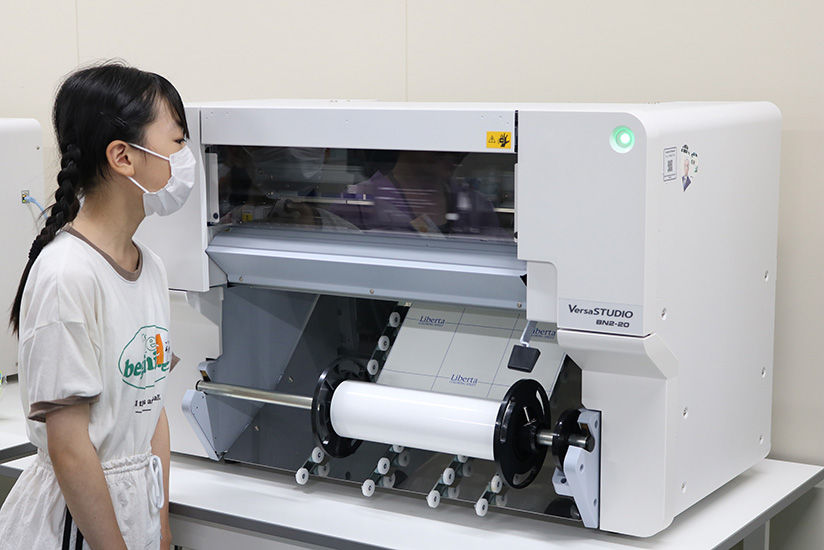

In addition, the VersaSTUDIO BN2-20 inkjet printer/cutter was used to produce stickers with the same design. Participants were interested in watching the process from printing to cutting being done in the printer. They also exchanged the finished stickers, which seemed to be an opportunity to get to know each other better.

-

Explanation by employees

-

Creating a design on the computer

-

Making designs seriously

-

Printing on transfer film with the TY-300

-

Design artwork heat pressed onto a tote bag

-

Peeling off the film to reveal the pattern

-

Printing stickers with the BN2-20

-

Participants were happy with the printed stickers

Understanding the appeal of the company and work

Participants came to the experience program as homework or memories of summer vacation.

The following impressions were received, and it encouraged us to participate again in the future.

“It was interesting to draw on a computer and print it on a tote bag.”

“I was impressed that I understood how printing works.”

“It was impressive to see it actually printed on a tote bag.”

“Thinking about the design in PowerPoint was very interesting.”

We also received comments from parents.

“I'm glad that my child could make a cute bag.”

“My child's sensibilities were stimulated when he saw a product with advanced technology.”

“I think my child felt the difficulty and fun of expressing what he liked.”

“My child was able to experience the process from design to product and feel the wonderfulness of manufacturing.”

The power of products to unleash creativity

The person in charge of our company who conducted the program recalled, “I think the process of creating a design from scratch with your own hands and giving shape to it led to children learning about manufacturing while having fun.” She also said, “I was surprised by the high level of creativity among the children, and at the same time, I was able to help bring out the creativity of children through this program and our products, and it was also a joy for us to make products.”

It was the first time for us to have children from the community come to our company, and we think they learned about our business, products, and work. It was also an opportunity for our employees to rediscover the appeal of our products from the excited expressions of the children. I would be happy if the children could take home the excitement of making things as a learning experience.